GTD MUD PUMPS

Mud pumps are essential components of drilling rigs. GTD offer a range of both ‘Centrifugal’ and ‘Piston’ pumps. Choosing the right pump/s to match the needs of your operation is crucial, as there are benefits and considerations for each pump type.

Often a combination of two pumps is preferential when outfitting a rig to enhance the efficiency and flexibility of your drilling operations. The GTD team is here to advise and help you make the right decision for your operation.

WHY WE NEED MUD PUMPS...

Mud pumps are indispensable in drilling shallow geothermal and water well boreholes. They circulate drilling mud that serves multiple critical functions: cooling and lubricating the drill bit, maintaining borehole stability, and carrying drill cuttings back to the surface. Mud pumps must deliver the necessary pressure and flow rate to push the drilling mud from the mud tank or recycling system, through the drill string, and then back to the surface. As the drilling depth increases, a more powerful pump is required-this is also true when dealing with drilling mud of higher viscosity.

Making the right choice

We have a wealth of real-world local knowledge of ‘what works where’ – so do reach out to determine what would be the most appropriate Mud Pump setup to outfit your rig with. There are different setups and common configurations depending on your region.

Outside of Europe, we advise our customers to outfit their rigs with both a reciprocating ‘Piston Pump’ and a Centrifugal Pump. The Piston Pump, provides high pressure, excelling in overcoming drilling resistance and ensuring thorough mud circulation. Alternatively, the Centrifugal Pump can be utilised to deliver high flow rates at a lower pressure when necessary. This dual pump setup can handle a broad range of drilling conditions, enhancing the adaptability and productivity of the operations.

In Europe, it is more typical to have a dual pump setup comprising of a Single Stage Centrifugal pump and a Multi Stage Centrifugal pump. The Single Stage pump delivers a high-high flow rate at lower pressure, or if necessary, the Multi Stage pump is invaluable in scenarios which require higher pressures.

We recommend the compatibility, efficiency and reliability of the mud pumps listed, when installed on our rigs. They have been exhaustively tested and proven in both R&D and commercial drilling scenarios. If you have a specific or different mud pump preference, please reach out to us for advice on its integration and compatibility with a GTD rig.

MUD PUMP OPTIONS :

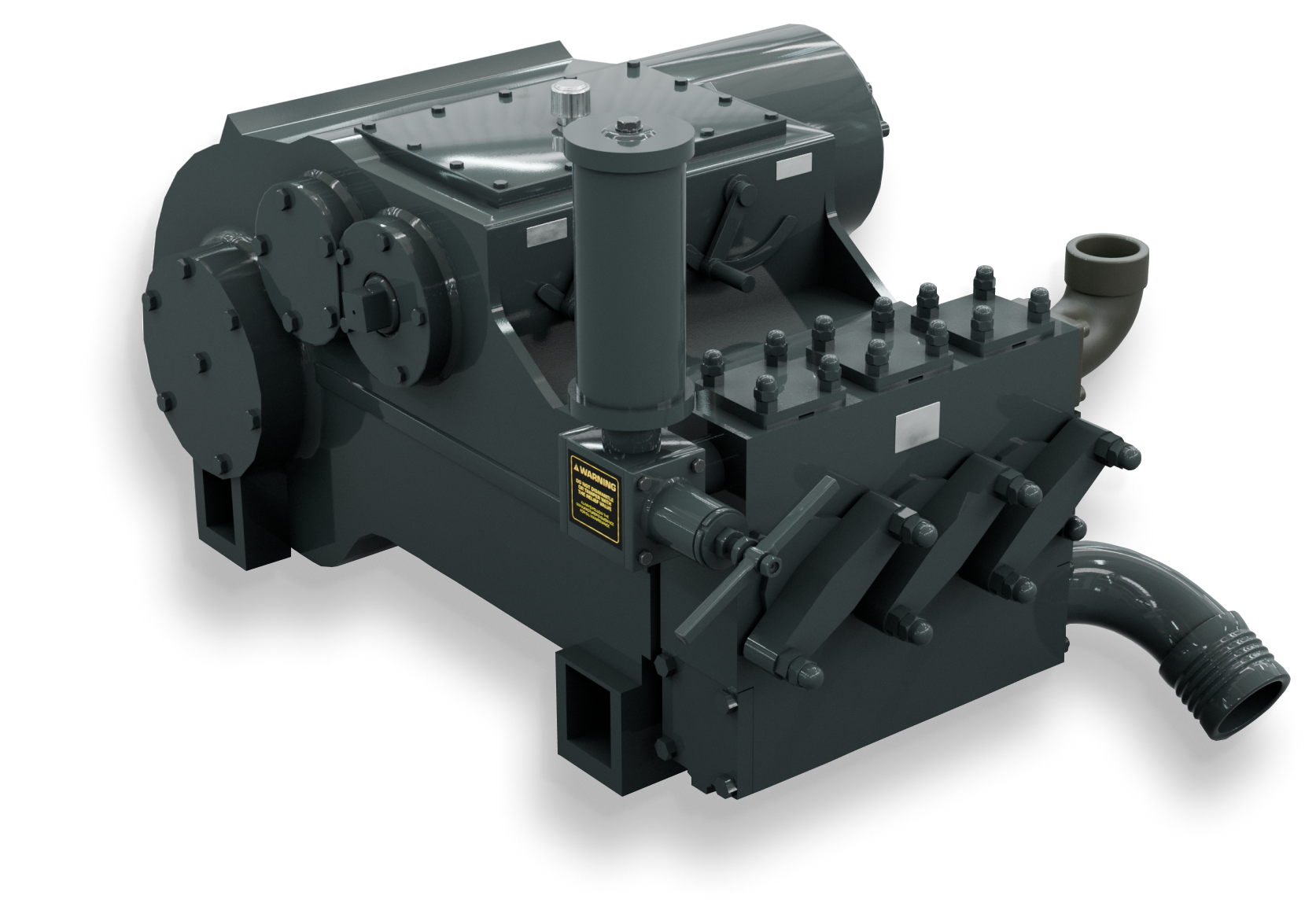

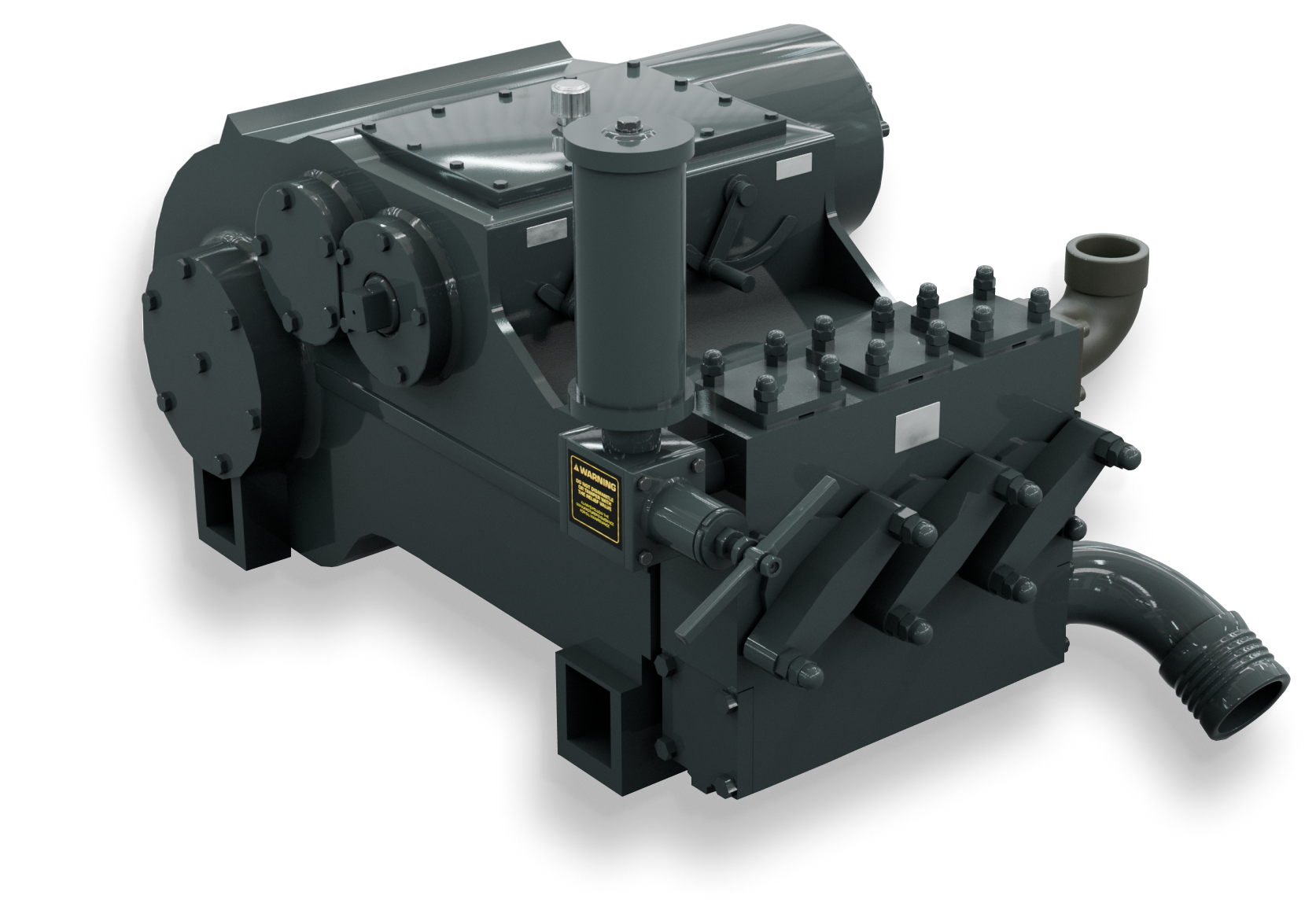

SINGLE ACTION 4.5 x 5.5 TRIPLEX PISTON MUD PUMP

Model: MP1000PP

- Flow: 264 gpm [1,000 lpm]

- Head: 1,300' [400 lpm]

- Pressure: 580 psi [40 bar]

- Feature: Ceramic Liners

- Core Benefits: High Pressure & High Flow

- Considerations: Purchase Price, Down time when rebuilding

SINGLE ACTION 5 x 6 TRIPLEX PISTON MUD PUMP

Model: MP1200PP

- Flow: 317 gpm [1,200 lpm]

- Head: 1,300' [400 lpm]

- Pressure: 580 psi [40 bar]

- Feature: Ceramic Liners

- Core Benefits: High Pressure & High Flow

- Considerations: Purchase Price, Down time when rebuilding

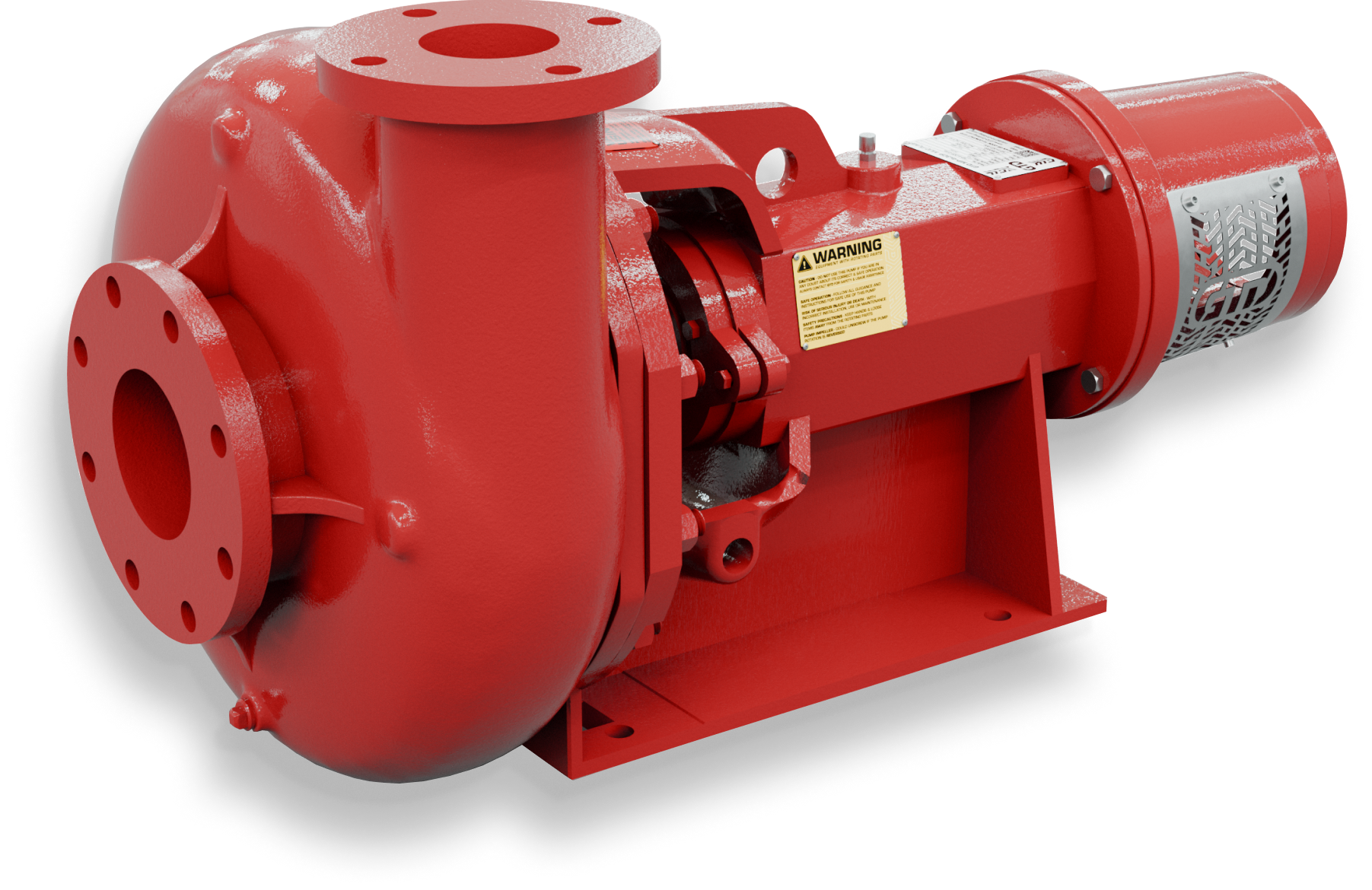

SINGLE STAGE 4 x 3 x 13 CENTRIFUGAL MUD PUMP

Model: MP-4x3x13CP-CrMo

- Impeller: 13"

- Flow: 317 gpm [1,200 lpm]

- Head: 558' [170 lpm]

- Pressure: 246 psi [17 bar]

- RPM: 2400

- High Chrome Alloy SA05 Impeller & Body

- Core Benefits: High Flow, Long Lasting

- Considerations: Lower Pressure

SPECS CAN BE INFORMATIVE...VIDEOS PROVIDE EVIDENCE...

It's why we share real-world drilling footage to validate why our equipment is the No.1 choice for geothermal industry leaders. See for yourself below:

GLOBAL PARTNERSHIPS

DRILLER FOCUSED SUPPORT

Our customer support stands out because we provide not only equipment assistance but also extensive drilling support as we are Drillers too, with decades of experience we are willing to share to help with your drilling operations.

More InfoGEOTHERMAL DRILLING RIGS

The GT series are proven for their high

productivity in Geothermal and Water Well

drilling in both domestic and commercial use.

MUD RECYCLING EQUIPMENT

Proper Mud Recycling equipment is essential to the drilling operation and a key part in increased productivity.

More Info

FACTORY TOUR

A behind-the-scenes tour of

GTD Desco’s state-of-the-art factory

and R&D center in South Korea

OUR STORY

We don’t just build rigs that are known for their ease of operation, efficiency, and safety. We are geothermal drillers to the core, equipped to deliver real-world drilling experience, knowledge, and specialist support service, not just for the machines but for the drilling too.

More Info