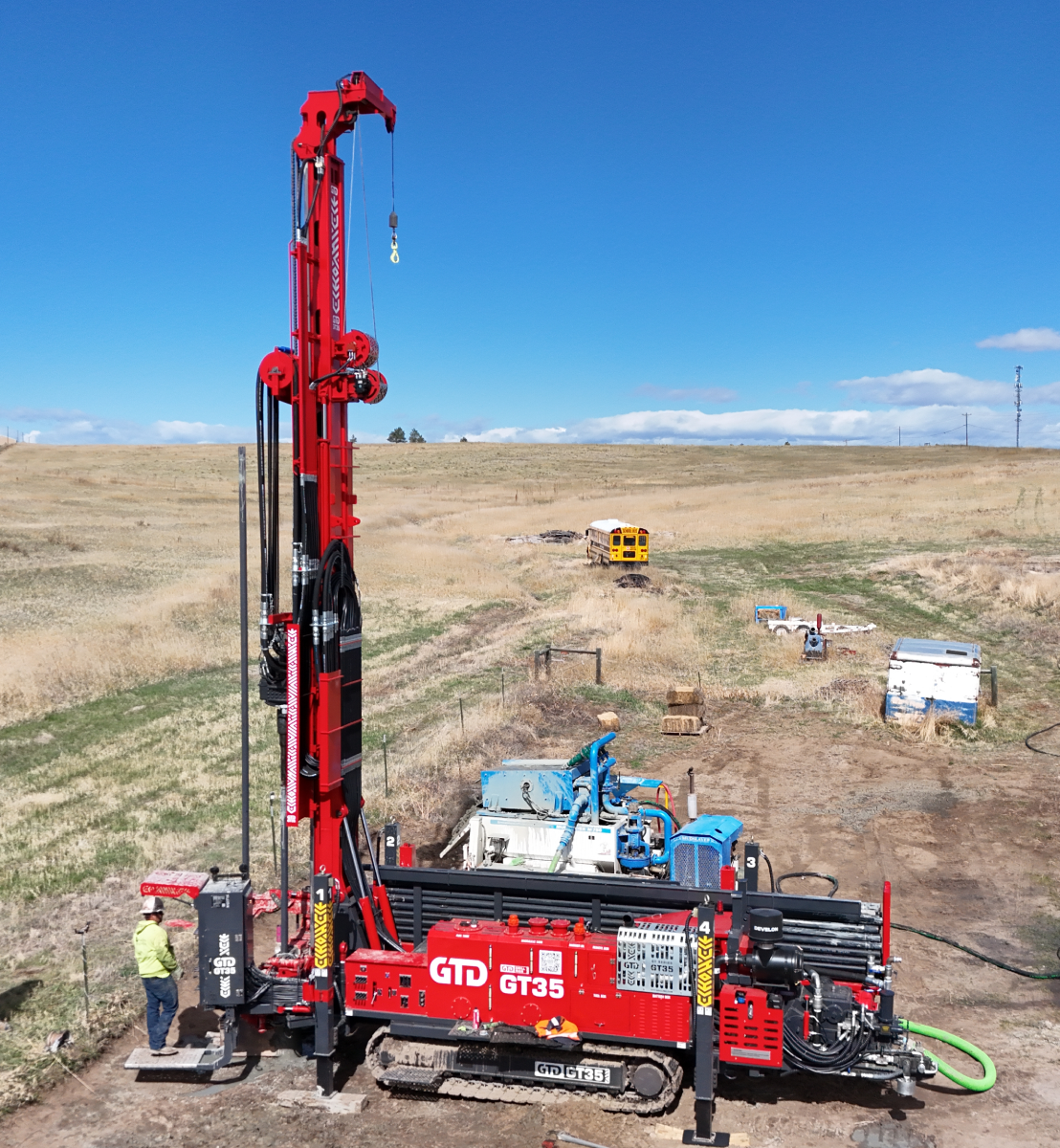

GT35 DRILL RIG

The GT35 geothermal & water well drill rig is designed to reach depths beyond 650ft using mud, air, and hammer drilling methods. It is equipped with our unique rod rack and loading system, which is the most robust, reliable, and safest rod handling system on the market, ensuring maximum safety and efficiency in all drilling operations.

DOWNLOAD SPEC SHEETGT35

-

35,000 LBS

PULL-BACK -

290HP

DOOSAN ENGINE -

20FT DRILL RODS

880FT ON BOARD RODS -

DRILL BEYOND

650FT

SPECIFICATIONS

DIMENSIONS & WEIGHT

- Length 38′ 7″ (11.8m)

- Width 7′ 8″ (2.4m)

- Height 10′ 3″ (3.2m)

- Weight 44,000 lbs – 55,000 lbs

(20,000 kg – 25,000 kg)

Actual weight will vary depending on the options selected and installed, e.g. Rods..

DERRICK & FEED SYSTEM

- 35,274 lbs (16,000 kg) pull-back

- 14,330 Ibs (6,500 kg) push-down

- 24′ 7″ (7.5 m) top head stroke

DRILL PIPE & CASING

- 3 ½” (88.9 mm) × 20′ (or 6 m)

40 rod capacity – 880′ (or 264 m) - Max diameter 12 ½” (320 mm)

ENGINE

- Doosan DL08 Tier 4 (Stage 5)

- 290 hp (213 kW)

- Typical engine speed – 1,400 rpm – 1,600 rpm

- Max engine speed – 1,800 rpm

ROTARY DRILL HEAD

- Variable twin Eaton motor head with 2.4″ (60 mm) thru-hole

- 0-135 rpm @ 6,195 lb-ft (8.4 kNm)

- 0-260 rpm @ 3,097 lb-ft (4.2 kNm)

CRAWLER (TRACK) BASE

- Doosan Solar 75

- Steel with rubber pads

- Wireless remote travel

GTD STANDARD FEATURES

- Sideshift – Sliding Drill Head

- Swivel & Floating Spindle Sub

- Height Adjustable Working Table

- Double Clamps – One Rotating

- Hydraulic Centralizing Rollers

- Hydraulic Breakout Chain Wrench

- Auxiliary Hydraulic Ports and Controls

- Main Winch – 11,000 lbs (5,000 kg)

- Wire/Sandline Winch

- Water Injection Mist Pump

- DTH Lube System

- Rod Rack & Rod Loader

- Hydraulic Welder & Generator (7.5Kw)

- Self Loading Jacks/ Outriggers

- Air Compressor: 24 cfm (673 lpm), 130 psi (9 bar)

- Centrifugal Pump: 4x3x13 Single-stage

- 4.5 x 5.5 Triplex Piston Pump:

264 gpm @ 580 psi (1,000 lpm @ 40 bar) - Tablet Computer & Engine Diagnostics Software

OPTIONS

- Hydraulic Sliding Rod Wrench

- Triple Clamps

- Angled Drilling

- Safety Cage

- Sandline Winch Length 1,000′ – 6,500′ (300m – 2,000m)

SPECS CAN BE INFORMATIVE...VIDEOS PROVIDE EVIDENCE...

It's why we share real-world drilling footage to validate why our equipment is the No.1 choice for geothermal industry leaders. See for yourself below:

OUR GT SERIES MODEL DRILL RIGS

The GT series drill rigs are proven for their high productivity in Geothermal and Water Well drilling in both domestic and commercial use. From our flagship Double-Head rig, featuring a Cummins X12 engine, to our smallest compact rig with Doosan power. All models are versatile machines, with full capability for Mud, Air or DTH drilling.

SINGLE HEAD DRILL RIGS

GT60

- 65,000 LBS PULL-BACK

- 513HP CUMMINS ENGINE

- 25FT DRILL RODS 1,200FT ON BOARD RODS

- EURODRILL TOP DRIVE - RH24X TORE OF 17,700 LB-FT

- DRILL BEYOND 1,000FT

- MORE INFO >

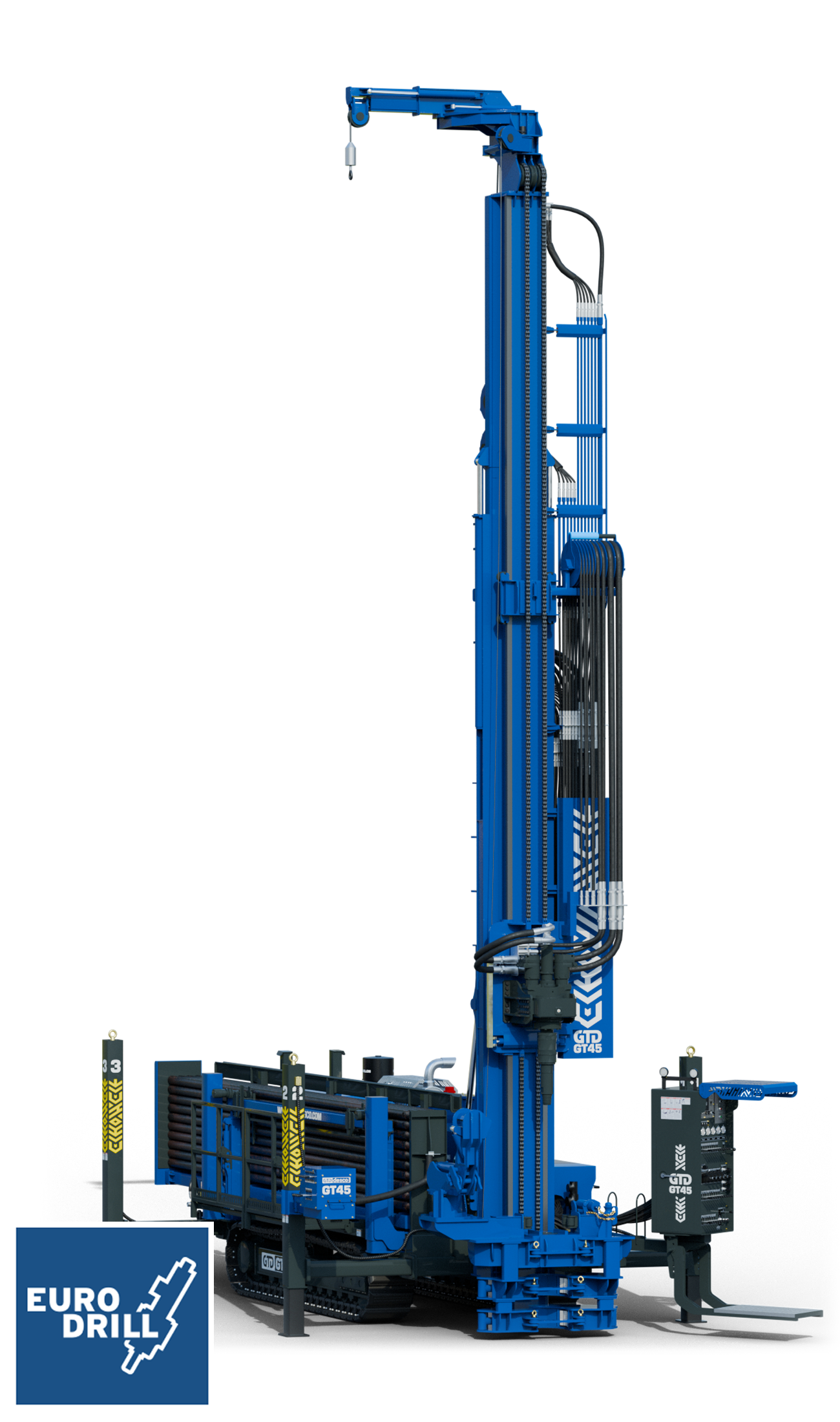

GT45

- 46,000 LBS PULL-BACK

- 380HP CUMMINS ENGINE

- 20FT DRILL RODS 880FT ON BOARD RODS

- EURODRILL TOP DRIVE - RH16X TORE OF 11,897 LB-FT

- DRILL BEYOND 850FT

- MORE INFO >

GT35

- 35,000 LBS PULL-BACK

- 290HP DOOSAN ENGINE

- 20FT DRILL RODS 880FT ON BOARD RODS

- DRILL BEYOND 650FT

- MORE INFO >

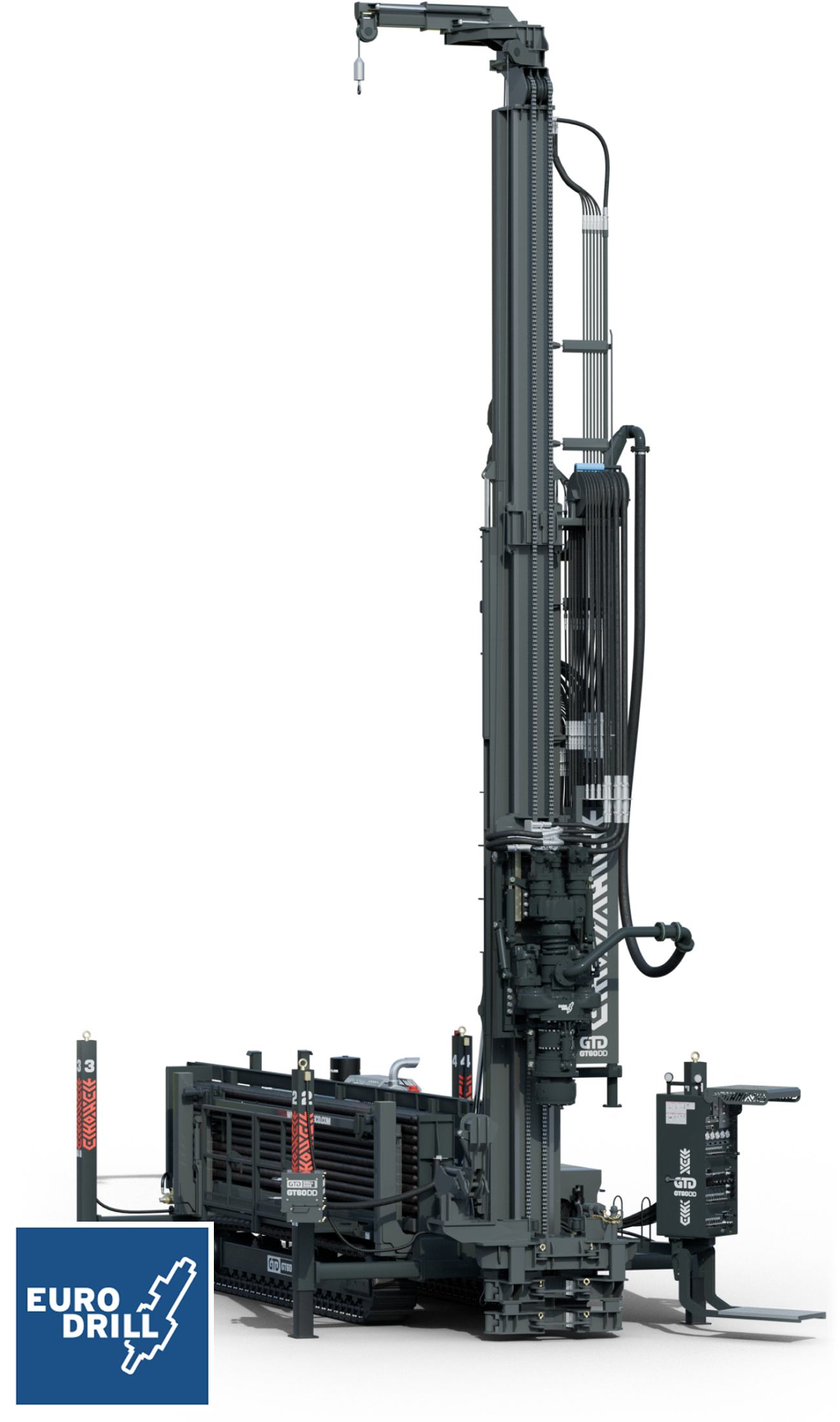

DOUBLE HEAD DRILL RIGS

GT60DD

- 65,000 LBS PULL-BACK

- 513HP CUMMINS ENGINE

- 25FT DRILL RODS 960FT ON BOARD RODS

- EURODRILL CASING DRIVE - RH40X TORE OF 29,500 LB-FT

- MORE INFO >

GT45DD

- 45,000 LBS PULL-BACK

- 380HP CUMMINS ENGINE

- 25FT DRILL RODS 800FT ON BOARD RODS

- EURODRILL CASING DRIVE - RH12X TORE OF 14,976 LB-FT

- MORE INFO >

THE GT60DD, GT45DD, GT60 and GT45 RIGS ARE ALL FITTED WITH EURODRILL HEADS AS STANDARD, WIDELY ACCEPTED AS THE BEST ON THE MARKET

DRILLER FOCUSED SUPPORT

Our customer support stands out because we provide not only equipment assistance but also extensive drilling support as we are Drillers too, with decades of experience we are willing to share to help with your drilling operations.

More InfoTRACKED CARRIERS

TC24 Tracked Carriers serve as a highly versatile and truly multifunctional tool, providing exceptional flexibility to efficiently transport and reliably power a wide variety of equipment, attachments, and specialized tooling across different jobs, while maintaining strong performance, stability, and operational efficiency.

More Info

SOLIDS CONTROL EQUIPMENT

Proper Mud Recycling Equipment is absolutely essential to the overall success of any drilling operation, playing a vital role in maintaining efficiency, reducing downtime, and ultimately serving as a key factor in significantly increasing productivity on site.

More Info

FACTORY TOUR

A behind-the-scenes tour of GTD Desco’s cutting-edge, state-of-the-art manufacturing factory and advanced R&D innovation center in South Korea, offering an in-depth look at our technology, development process, and world-class engineering capabilities.

More InfoOUR STORY

We don’t just build rigs that are known for their ease of operation, efficiency, and safety. We are geothermal drillers to the core, equipped to deliver real-world drilling experience, knowledge, and specialist support service, not just for the machines but for the drilling too.

More Info