SOLIDS CONTROL EQUIPMENT

The MG500 mud recycling system can process and separate up to 400 – 500 gallons per minute (1,500 – 1,900 Lpm) of drilling fluid, with a separation point of down to 15 micrometers.

KEY SPECIFICATIONS & FEATURES

DIMENSIONS & WEIGHT

- Length 20′ 9″ (6.3 m)

- Width 7′ 8″ (2.3 m)

- Height 11′ 6″ (3.5 m)

- Weight 30,800 lbs (14,000 kg)

MUD SYSTEM

- Shale Shaker Deck: 8x 5″ cones and huge shaker area of 3.408m² (36.68 ft²)

- Screens: API 60 Mesh / API 80 Mesh

(Changeable to meet site needs) - Desilter Hydrocyclones (Cones): 8 x 5”

(Separation down to 15 micrometers) - Combined Capacity: 1,665 Gallons (6,300 Liters)

Main Tank Capacity: 925 Gallons (3,500 Liters)

Mud Mixing / Storage Tank Capacity: 740 Gallons (2,800 Liters) - Centrifugal Pump: two 4x3x13 Single Stage

- V-shaped tank design (minimizes solids build-up)

- OLI 7 G-force linear motors: For increased

processing capacity over hydraulic optical motors. - Pump back to rig capability:

For priming and supercharging mud drilling pumps. - Adjustable shaker angle of -10°/+6°:

For easy fine tuning to changes in geology. - API RP 13C Oil & Gas shaker screens:

For superior performance and reliability. - Venturi Mud Mixing Hopper

Mixes powdered mud products with ease.

TRACKED CARRIER

- Model SOLAR 75

- Tracking Speed (Lo-Hi)

1.5 mph (2.5 kmh) ~ 2.5 mph (4.0 kmh) - Gradeability 25°

- Track Width 17.7″ (450 mm)

- Steel with rubber pads

ENGINE

- Doosan DM03 (Stage V)

- 110 hp (82 kW)

- Fuel Tank 32 gal (120 liters)

- 12V DC

HYDRAULIC SYSTEM

- Flow Rate <42 gpm (<160 lpm)

- Operating Pressure 3,626 psi (250 bar)

- Hyd. Oil Tank 266 gal (100 liters)

SPECS CAN BE INFORMATIVE...VIDEOS PROVIDE EVIDENCE...

It's why we share real-world drilling footage to validate why our equipment is the No.1 choice for geothermal industry leaders. See for yourself below:

DRILLER FOCUSED SUPPORT

We don’t just build rigs that are known for their ease of operation, efficiency, and safety. We are geothermal drillers to the core, equipped to deliver real-world drilling experience, knowledge, and specialist support service, not just for the machines but for the drilling too.

More InfoGEOTHERMAL DRILLING RIGS

The GT Series Drill Rigs are proven for their outstanding reliability and consistent high productivity, delivering exceptional performance in both Geothermal and Water Well drilling applications across a wide range of environments, making them ideal for domestic projects as well as demanding commercial use.

More Info

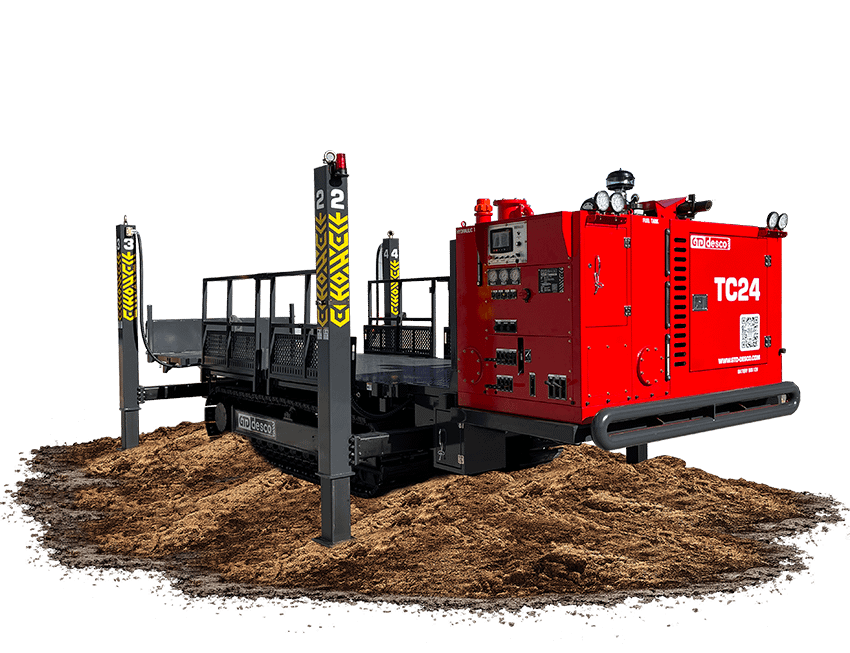

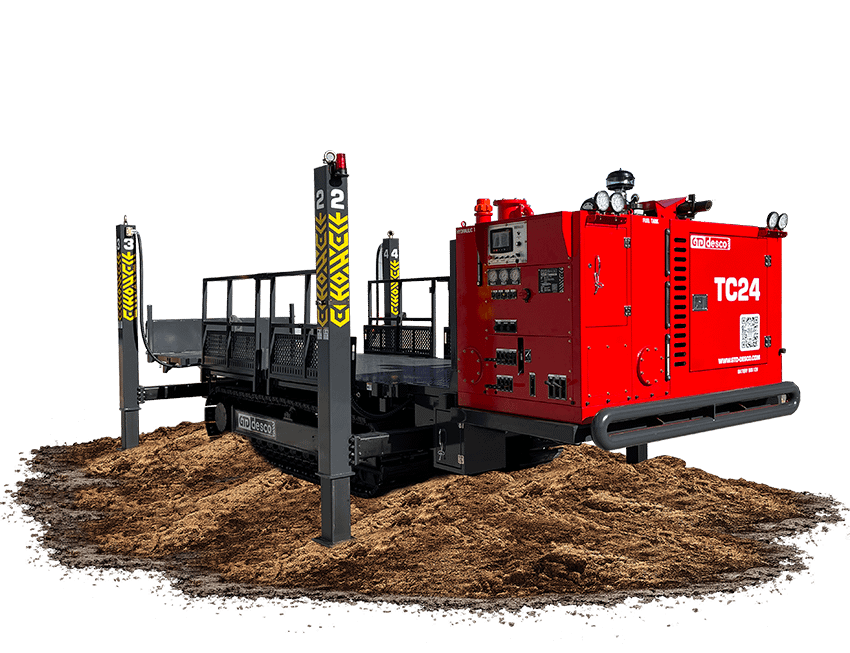

TRACKED CARRIERS

TC24 Tracked Carriers serve as a highly versatile and truly multifunctional tool, providing exceptional flexibility to efficiently transport and reliably power a wide variety of equipment, attachments, and specialized tooling across different jobs, while maintaining strong performance, stability, and operational efficiency.

More Info

DOUBLE HEAD DRILL RIGS

GT65DR

- 65,000 LBS PULL-BACK

- 513HP CUMMINS ENGINE

- 25FT DRILL RODS 960FT ON BOARD RODS

- EURODRILL TOP DRIVE - RH24X TORQUE OF 17,700 LB-FT

- DRILL BEYOND 1000ft

- MORE INFO >

GT45DR

- 45,000 LBS PULL-BACK

- 380HP CUMMINS ENGINE

- 25FT DRILL RODS 800FT ON BOARD RODS

- EURODRILL TOP DRIVE - RH16X TORQUE OF 14,976 LB-FT

- DRILL BEYOND 850ft

- MORE INFO >

THE GT65DR, GT45DR, GT65 and GT45 RIGS ARE ALL FITTED WITH EURODRILL HEADS AS STANDARD, WIDELY ACCEPTED AS THE BEST ON THE MARKET

FACTORY TOUR

A behind-the-scenes tour of GTD Desco’s cutting-edge, state-of-the-art manufacturing factory and advanced R&D innovation center in South Korea, offering an in-depth look at our technology, development process, and world-class engineering capabilities.

More InfoOUR STORY

We don’t just build rigs that are known for their ease of operation, efficiency, and safety. We are geothermal drillers to the core, equipped to deliver real-world drilling experience, knowledge, and specialist support service, not just for the machines but for the drilling too.

More Info